Metal Associates

Distributors of Ferrous and Non-Ferrous Metals

Specializing in Copper, Brass, & Bronze

What is a Waveguide?

A waveguide is a physical structure or device that is used to guide electromagnetic waves, such as radio waves, microwaves, or light waves, from one point to another. The basic function of a waveguide is to provide a path for electromagnetic waves while minimizing their loss and maintaining their integrity.

Waveguides can be used to guide any particular type of wave such as sound waves, electromagnetic waves, or radio waves. Waveguides are not new, but we now understand more about how they work so that they can be manufactured for many different uses. Today, waveguide technology is used in everything from optic fibers to microwaves to radars.

Waveguide Materials

There are a number of ways Metal Associates can create your waveguide solutions. We’ll work with you to determine exactly which machining process is best for your application. Waveguides can be manufactured from dielectric or conductive or dielectric materials depending on the wave frequency.

-

Conductive Waveguides:

Material Characteristics: Conductive waveguides, as the name suggests, are made of materials with high electrical conductivity. Common materials include metals such as copper, aluminum, and bronze.[S2]

Propagation Mechanism: Electromagnetic waves in conductive waveguides travel along the surface of the conductor, guided by the metal walls. This is often referred to as surface wave propagation.

Applications: Conductive waveguides are frequently used in microwave and RF (radio frequency) systems. Examples include rectangular waveguides and coaxial cables. They are essential for guiding and transmitting high-frequency signals efficiently.

-

Dielectric Waveguides:

Material Characteristics: Dielectric waveguides are typically made of non-conductive materials, often dielectric or insulating materials. Common dielectric materials include glass, plastic, ceramics, and certain types of polymers.

Propagation Mechanism: In dielectric waveguides, electromagnetic waves propagate by total internal reflection within the dielectric material. This means that the waves are confined within the material and are reflected back into it if they attempt to escape.

Applications: Dielectric waveguides are commonly used in optical communication systems, such as optical fibers. They are also employed in microwave and millimeter-wave systems.

Factors Influencing Waveguide Material Selection

- Frequency Range: The choice between dielectric and conductive waveguides depends on the frequency range of the signals being transmitted. Conductive materials are more suitable for higher frequencies, while dielectric materials are often used at lower frequencies.

- Losses: Dielectric materials generally have lower losses at lower frequencies. However, at higher frequencies, conductive materials may be preferred to minimize signal attenuation.

- Manufacturability: The ease of manufacturing and cost considerations also influence the selection of waveguide materials.

Types of Waveguides Offered by Metal Associates

-

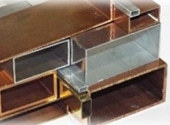

Thin and Heavy Wall Waveguide Tubing

Thin Wall: Refers to waveguide tubing with a relatively thin cross-sectional wall. This design is often used when weight or space considerations are crucial.

Heavy Wall: In contrast, heavy wall waveguide tubing has a thicker cross-sectional wall. This design is chosen when durability, rigidity, or specific mechanical properties are required.

-

Reduced Heights Waveguide Tubing

This type of waveguide tubing is designed with reduced height dimensions. It is used in situations where space constraints or a lower profile are important considerations.

-

Copper Waveguide Tubing

Made of copper, this type of waveguide tubing is often used for its excellent electrical conductivity. Copper waveguides are commonly used in high-frequency systems.

-

Brass/Bronze Waveguide Tubing

Brass and bronze waveguide tubing combines the electrical conductivity of copper with the corrosion resistance of these alloys. This can be advantageous in environments where corrosion is a concern.

-

Aluminum Waveguide Tubing

Aluminum waveguide tubing is known for its lightweight nature. It is commonly used in situations where weight is a critical factor, and electrical conductivity comparable to copper is acceptable.

-

Cupro-Nickel Waveguide Tubing*

Cupro-nickel waveguide tubing is made from a copper-nickel alloy. This alloy provides a balance between electrical conductivity and corrosion resistance, making it suitable for marine and other harsh environments.

-

Invar (Nickel Alloy) Waveguide Tubing*

Invar is a nickel-iron alloy with low thermal expansion properties. Invar waveguide tubing is used in applications where dimensional stability over a range of temperatures is crucial, such as in precision instruments and aerospace applications.

-

Seamless Flexible Waveguide

Flexible waveguides are made from interlocked sections of folded metal that may be soldered to seal the seams. While the waveguide channel remains straight, flexion allows for applications where rigid waveguides would be too complex or expensive.

|

Type of Waveguide

|

Durability/Rigidity

|

Electrical Conductivity

|

Thermal Expansion

|

Corrosion Resistance

|

|

Copper

|

High (Heavy Wall: Very High; Thin Wall: Moderate)

|

Excellent (99.95%–99.99% purity, ideal for high-frequency systems)

|

High (expands significantly with temperature)

|

Moderate (susceptible to oxidation, requires coatings for harsh environments)

|

|

Brass

|

Moderate to High (Heavy Wall: High; Thin Wall: Moderate)

|

Good (lower than copper but sufficient for RF systems)

|

Moderate (less than copper, zinc content stabilizes)

|

High (zinc enhances corrosion resistance)

|

|

Bronze

|

High (Heavy Wall: Very High; Thin Wall: Moderate)

|

Good (similar to brass, suitable for waveguides)

|

Moderate (comparable to brass, alloy-dependent)

|

Very High (excellent corrosion resistance, ideal for marine environments)

|

|

Aluminum

|

Moderate (Heavy Wall: High; Thin Wall: Lower due to softness)

|

Very Good (high conductivity, used in lightweight applications)

|

High (expands more than steel but less than copper)

|

Good (forms protective oxide layer, resists corrosion)

|

|

Invar

(Nickel Alloy) |

Very High (excellent mechanical stability, rigid even in Thin Wall)

|

Moderate (lower conductivity than copper or aluminum)

|

Very Low (designed for minimal thermal expansion)

|

High (nickel enhances corrosion resistance)

|

Waveguide Shapes

Rectangular, circular, oval, and square waveguide tubing are different shapes of structures used in the field of waveguide technology for guiding and transmitting electromagnetic waves. Each shape has its own set of characteristics and applications. Here are the key differences between them:

-

Rectangular Waveguide Tubing:

Shape: Rectangular cross-section.

Advantages:

- Easy to fabricate and install.

- Well-suited for guiding TE (Transverse Electric) and TM (Transverse Magnetic) modes.

Applications:

- Commonly used in radar systems, microwave communication, and high-frequency electronic devices.

-

Circular Waveguide Tubing:

Shape: Circular cross-section.

Advantages:

- Circular waveguides have no cutoff frequency for the dominant mode.

- Can support only one mode (TE11 mode) and is not suitable for higher modes.

Applications:

- Used in satellite communication, microwave antennas, and where circular polarization is preferred.

-

Oval Waveguide Tubing:

Shape: Elliptical or oval cross-section.

Advantages:

- Combines some advantages of both rectangular and circular waveguides.

- Can be used to control polarization and reduce cross-polarization.

Applications:

- Used where a balance between circular and rectangular waveguides is needed.

-

Square Waveguide Tubing:

Shape:Square cross-section.

Advantages:

- Similar advantages to rectangular waveguides.

- Suitable for guiding both TE and TM modes.

Applications:

- Commonly used in microwave and millimeter-wave applications, including radar and communication systems.

Key Considerations:

- The choice of waveguide shape depends on the specific requirements of the application, such as frequency range, mode support, and polarization.

- Circular waveguides are often preferred for minimizing mode competition and ensuring a single dominant mode, while rectangular and square waveguides are more versatile in supporting multiple modes.

- Oval waveguides provide a compromise between the advantages of rectangular and circular waveguides, offering flexibility in polarization control.

*Can be available upon special request

Custom sized to exact specifications

All Waveguide Tubing is available in a variety of standard materials

Metal Associates is a supplier of:

- WR 8 Copper

- WR 10 Copper

- WR 12 Copper

- WR 15 Copper

- WR 19 Copper

- WR 22 Copper

- WR 28 Copper, Aluminum and Bronze

- WR 34 Copper, Aluminum and Bronze

- WR 42 Copper, Aluminum and Bronze

- WR 51 Copper, Aluminum and Bronze

- WR 62 Copper, Aluminum and Bronze

- WR 63 Copper

- WR 75 Copper, Aluminum and Bronze

- WR 85 Copper

- WR 90 Copper, Aluminum and Bronze

- WR 92 Copper

- WR 102 Aluminum

- WR 112 Copper, Aluminum and Bronze

- WR 137 Copper, Aluminum and Bronze

- WR 159 Copper and Aluminum

- WR 187 Copper and Aluminum

- WR 229 Copper and Aluminum

- WR 284 Copper, Aluminum and Bronze

Other sizes can be produced upon special request

Waveguides are structures that guide electromagnetic waves, such as microwaves or light, from one point to another. The materials used to construct waveguides depend on the frequency range of the waves they are designed to guide. Here are some common materials used for different types of waveguides:

-

Metallic Waveguides (Microwave Frequencies):

Copper: Copper is a common material for waveguides at microwave frequencies. It offers low losses and good conductivity.

Aluminum: Aluminum is also used for waveguides, especially in applications where weight is a concern.

-

Dielectric Waveguides (Optical Frequencies):

Silicon: Silicon is commonly used for optical waveguides, particularly in integrated optics applications.

Glass: Various types of glasses, such as silica (quartz) or other specialty glasses, can be used for optical waveguides.

-

Optical Fiber (Telecommunications):

Silica (Glass): Optical fibers, which are a type of waveguide used in telecommunications, are typically made of silica glass.

-

Plastic or Polymer Waveguides:

Polymer Materials:In some applications, especially in integrated optics or for flexible waveguides, polymers, and plastic materials may be used.

-

Photonic Crystal Waveguides:

Semiconductor Materials: For photonic crystal waveguides, semiconductor materials such as silicon are commonly used.

The choice of material depends on factors such as the frequency range of the guided waves, the desired properties of the waveguide (such as low losses or flexibility), and the specific application requirements. Different materials offer different advantages and trade-offs, and the selection is often tailored to meet the needs of the particular waveguide application.

Material Selection for Frequency Specific Applications

Different alloys offer different combinations of conductivity, rigidity, thermal behavior, and corrosion resistance. Metal Associates evaluates operating frequency, environmental exposure, and mechanical requirements to match each project with the appropriate material. Options include copper for high conductivity, aluminum for reduced weight, brass and bronze for improved corrosion resistance, and Invar for low thermal expansion.Supply Chain Support for Regional Manufacturers

Manufacturers in New Jersey rely on predictable lead times and consistent material availability. Metal Associates supports scheduled releases, blanket orders, and recurring shipments for customers building RF modules, communication systems, and microwave assemblies. Our access to multiple mills ensures stable supply for both standard WR sizes and non standard configurations.FAQ

Do You Supply Waveguide Tubing in Standard WR Sizes?

Yes. Metal Associates provides a full range of WR sizes in copper, aluminum, bronze, and other alloys, with additional sizes available upon request.Can Waveguide Tubing Be Cut or Processed Before Delivery?

Yes. Cutting, machining, and preparation for flanges or transitions can be completed prior to shipment to support system integration.Which Materials Are Best for High Frequency Applications?

Copper and aluminum are commonly selected for their conductivity and stable performance at microwave frequencies. Material selection depends on frequency, environment, and mechanical requirements.Do You Support Both Prototype and Production Quantities?

Yes. Metal Associates supplies small batch orders for development work as well as high volume programs for ongoing manufacturing.Metal Associates - A Leading Waveguide Manufacturer

Metal Associates is an exclusive waveguide distributor for copper and bronze manufacturers in the USA. We are also an exclusive waveguide tube distributor for an aluminum manufacturing mill that is located in the UK.

Metal Associates offers Rigid Waveguide Tubes including rectangular, circular and double ridge waveguides. Our square waveguides can be manufactured in the range from Q41 to Q130. We also supply non-standard types as listed below in a variety of standard materials such as Copper, Bronze, Brass, Aluminum, Nickel Iron, and more.* (see * on webpage)

If you would like to request a quote or learn more about our waveguide solutions, contact us today.

Our Other Products

Contact Us

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com