Metal Associates

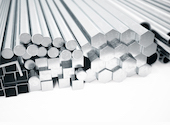

Distributors of Ferrous and Non-Ferrous Metals

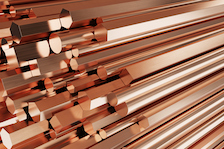

Specializing in Copper, Brass, & Bronze

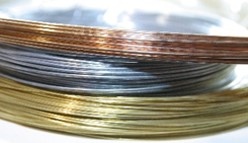

Copper, Brass & Bronze Wire

Metal Associates has established relationships with wire manufacturers that custom draws round, flat, square, and shaped wire to your exact specifications. Our products meet the needs of various industries, including electronics and microwave technology. We have a team of experts that can assist with your project requirements.

Metal Associates has established relationships with wire manufacturers that custom draws round, flat, square, and shaped wire to your exact specifications. Our products meet the needs of various industries, including electronics and microwave technology. We have a team of experts that can assist with your project requirements.

What can Metal Associates do for you? Apart from having a wide range of wire products including Copper, Brass, and Bronze wire we offer services such as re-rolling, leveling, and slitting. We go beyond delivering, meeting the highest standards in every project.

Metal Associates also provides various alloys, such as copper, brass, bronze, beryllium copper, nickel, steel, stainless steel, aluminum, and more. All our wires have come through tempering processes. We provide plating in various products such as cadmium, silver, tin, gold (and more) or anodized.

Copper Wire

Corrosion and wire resistance are important factors when producing wire that needs to withstand harsh conditions. Copper wires are known for their electric and thermal conductivity and are corrosion and wear-resistant, cost-effective and easy to maintain. Because of its ductility and malleability, copper can be formed into different shapes. An added quality is that copper is environmentally friendly because it can be recycled.

Corrosion and wire resistance are important factors when producing wire that needs to withstand harsh conditions. Copper wires are known for their electric and thermal conductivity and are corrosion and wear-resistant, cost-effective and easy to maintain. Because of its ductility and malleability, copper can be formed into different shapes. An added quality is that copper is environmentally friendly because it can be recycled.

Brass Wire

Brass wire is the perfect material to use when manufacturing electrical components due to the fact that it is corrosion resistant and has conductive properties. These conductive properties come from the copper and zinc composition of brass wire. Because of its durability, these wires are used for electrical connectors. The lightweight and malleable brass strips are excellent to use in small diameter applications. The brass wire can be cut in any length, dimensions, or shapes.

Bronze Wire

Bronze is a composition of copper and tin that is strong, corrosion and fatigue resistant, and withstands harsh conditions. The electronic industry uses bronze wire in numerous applications because it is an excellent conductor of heat and current. Bronze coils have become a major role player in the automotive manufacturing and marine technology industries due to its resistance to fatigue when placed under stress and high-pressure conditions.

Benefits and Applications of Wire Products

Every application has its unique specifications and requirements, from metal choice, size, length, kind of tempering, etc. Many projects may include several different combinations of wiring and electrical components.

Every application has its unique specifications and requirements, from metal choice, size, length, kind of tempering, etc. Many projects may include several different combinations of wiring and electrical components.

Copper Wire

Because current flows easily through copper with little resistance and no energy loss it is used in main cables, underground cables, and in houses. Tall buildings use copper strips as lightning conductors. Copper wire, wound into coils, produces magnetic fields and is used in applications to generate electricity.

Brass Wire

Brass provides cost-effective solutions. The wire can be drawn into very thin wires and has little resistance to current. It is ideal for industrial projects such as cables, long-distance power supply, as well as underground trains. The brass wire can be flat or rounded and is annealed.

Bronze Wire

Bronze, like copper and brass, is a good conductor of current and heat and is ideal for electronic parts. It has become popular since the rise of electric cars. For many years bronze wire and other bronze parts have been used in boats, jet skis, etc.

Aluminum Wire

Aluminum is used for wiring due to its ratio to light weight conductivity. Aluminum is preferred to copper in applications of overhead power lines. Airplanes are also wired with aluminum wiring.

Aluminum is used for wiring due to its ratio to light weight conductivity. Aluminum is preferred to copper in applications of overhead power lines. Airplanes are also wired with aluminum wiring.

Beryllium Copper Wire

This product is also known as spring copper or beryllium bronze. Because of its strength, as well as it's non-magnetic and non-sparking qualities, it is excellent for metalworking. Beryllium copper is used for various parts of the aerospace industry.

What Are Your Wire Material Options?

Alloys Offered by Metal Associates for Wire Fabrication:

We offer many alloy options, as well as standard metal options.

Our copper offerings include:

Our copper offerings include:

- CDA 101, 102 OFHC

- CDA 107 Silver Bearing OFHC

- CDA 110 Electrolytic Tough Pitch

- CDA 113, 114, 117 Silver Bearing

- CDA 122 DHP

- CDA 145 Tellurium Copper

- CDA 150 AMZIRC, Zirconium Copper

- CDA 162 Cadmium Copper

- CDA 172, 173, 175, 17510 Beryllium Copper

- CDA 182 Chromium Copper

- CDA 187 Leaded Copper

- CDA 194, 195 Iron Bearing Copper

Our brass offerings include:

Our brass offerings include:

- CDA 210 Guilding Brass

- CDA 220 Commercial Bronze

- CDA 230 Red Brass

- CDA 240 Rich Low Brass

- CDA 260 Cartridge Brass

- CDA 268, 272 Yellow Brass

- CDA 280 Muntz Metal

- CDA 314 Leaded Commercial Brass

- CDA 330 Low Leaded Tube Brass

- CDA 353, 356 High Leaded Brass

- CDA 360 Free Cutting Brass

- CDA 464 Naval Brass

- CDA 482, 485 Leaded Naval Brass

Finally, our bronze offerings include:

Finally, our bronze offerings include:

- CDA 510 Grade "A" Phosphor Bronze

- CDA 511 Phosphor Bronze

- CDA 521 Grade "C" Phosphor Bronze

- CDA 544 B-2 Phosphor Bronze

- CDA 630 Nickel Bearing Aluminum Bronze

- CDA 642 Aluminum Silicon Bronze

- CDA 651, 655 Silicon Bronze

- CDA 675 Manganese Bronze

- CDA 706 Cupro-Nickel 10%

- CDA 715 Cupro-Nickel 30%

- CDA 725 Cupro-Nickel

- CDA 752, 762, 770 Nickel Silver

- CDA 932 Bearing Bronze

- CDA 954 Aluminum Bronze

Bronze Wire

Bronze is a composition of copper and tin that is strong, corrosion and fatigue resistant, and withstands harsh conditions. The electronic industry uses bronze wire in numerous applications because it is an excellent conductor of heat and current. Bronze coils have become a major role player in the automotive manufacturing and marine technology industries due to its resistance to fatigue when placed under stress and high-pressure conditions.

Benefits and Applications of Wire Products

Every application has its unique specifications and requirements, from metal choice, size, length, kind of tempering, etc. Many projects may include several different combinations of wiring and electrical components.

Every application has its unique specifications and requirements, from metal choice, size, length, kind of tempering, etc. Many projects may include several different combinations of wiring and electrical components.

Copper Wire

Because current flows easily through copper with little resistance and no energy loss it is used in main cables, underground cables, and in houses. Tall buildings use copper strips as lightning conductors. Copper wire, wound into coils, produces magnetic fields and is used in applications to generate electricity.

Brass Wire

Brass provides cost-effective solutions. The wire can be drawn into very thin wires and has little resistance to current. It is ideal for industrial projects such as cables, long-distance power supply, as well as underground trains. The brass wire can be flat or rounded and is annealed.

Bronze Wire

Bronze, like copper and brass, is a good conductor of current and heat and is ideal for electronic parts. It has become popular since the rise of electric cars. For many years bronze wire and other bronze parts have been used in boats, jet skis, etc.

Aluminum Wire

Aluminum is used for wiring due to its ratio to light weight conductivity. Aluminum is preferred to copper in applications of overhead power lines. Airplanes are also wired with aluminum wiring.

Aluminum is used for wiring due to its ratio to light weight conductivity. Aluminum is preferred to copper in applications of overhead power lines. Airplanes are also wired with aluminum wiring.

Beryllium Copper Wire

This product is also known as spring copper or beryllium bronze. Because of its strength, as well as it's non-magnetic and non-sparking qualities, it is excellent for metalworking. Beryllium copper is used for various parts of the aerospace industry.

What Are Your Wire Material Options?

Alloys Offered by Metal Associates for Wire Fabrication:

We offer many alloy options, as well as standard metal options.

Our copper offerings include:

Our copper offerings include:

- CDA 101, 102 OFHC

- CDA 107 Silver Bearing OFHC

- CDA 110 Electrolytic Tough Pitch

- CDA 113, 114, 117 Silver Bearing

- CDA 122 DHP

- CDA 145 Tellurium Copper

- CDA 150 AMZIRC, Zirconium Copper

- CDA 162 Cadmium Copper

- CDA 172, 173, 175, 17510 Beryllium Copper

- CDA 182 Chromium Copper

- CDA 187 Leaded Copper

- CDA 194, 195 Iron Bearing Copper

Our brass offerings include:

Our brass offerings include:

- CDA 210 Guilding Brass

- CDA 220 Commercial Bronze

- CDA 230 Red Brass

- CDA 240 Rich Low Brass

- CDA 260 Cartridge Brass

- CDA 268, 272 Yellow Brass

- CDA 280 Muntz Metal

- CDA 314 Leaded Commercial Brass

- CDA 330 Low Leaded Tube Brass

- CDA 353, 356 High Leaded Brass

- CDA 360 Free Cutting Brass

- CDA 464 Naval Brass

- CDA 482, 485 Leaded Naval Brass

Finally, our bronze offerings include:

Finally, our bronze offerings include:

- CDA 510 Grade "A" Phosphor Bronze

- CDA 511 Phosphor Bronze

- CDA 521 Grade "C" Phosphor Bronze

- CDA 544 B-2 Phosphor Bronze

- CDA 630 Nickel Bearing Aluminum Bronze

- CDA 642 Aluminum Silicon Bronze

- CDA 651, 655 Silicon Bronze

- CDA 675 Manganese Bronze

- CDA 706 Cupro-Nickel 10%

- CDA 715 Cupro-Nickel 30%

- CDA 725 Cupro-Nickel

- CDA 752, 762, 770 Nickel Silver

- CDA 932 Bearing Bronze

- CDA 954 Aluminum Bronze

Every application has its unique specifications and requirements, from metal choice, size, length, kind of tempering, etc. Many projects may include several different combinations of wiring and electrical components.

Every application has its unique specifications and requirements, from metal choice, size, length, kind of tempering, etc. Many projects may include several different combinations of wiring and electrical components.

Copper Wire

Because current flows easily through copper with little resistance and no energy loss it is used in main cables, underground cables, and in houses. Tall buildings use copper strips as lightning conductors. Copper wire, wound into coils, produces magnetic fields and is used in applications to generate electricity.Brass Wire

Brass provides cost-effective solutions. The wire can be drawn into very thin wires and has little resistance to current. It is ideal for industrial projects such as cables, long-distance power supply, as well as underground trains. The brass wire can be flat or rounded and is annealed.Bronze Wire

Bronze, like copper and brass, is a good conductor of current and heat and is ideal for electronic parts. It has become popular since the rise of electric cars. For many years bronze wire and other bronze parts have been used in boats, jet skis, etc.Aluminum Wire

Aluminum is used for wiring due to its ratio to light weight conductivity. Aluminum is preferred to copper in applications of overhead power lines. Airplanes are also wired with aluminum wiring.

Aluminum is used for wiring due to its ratio to light weight conductivity. Aluminum is preferred to copper in applications of overhead power lines. Airplanes are also wired with aluminum wiring.

Beryllium Copper Wire

This product is also known as spring copper or beryllium bronze. Because of its strength, as well as it's non-magnetic and non-sparking qualities, it is excellent for metalworking. Beryllium copper is used for various parts of the aerospace industry.What Are Your Wire Material Options?

Alloys Offered by Metal Associates for Wire Fabrication:We offer many alloy options, as well as standard metal options.

- CDA 101, 102 OFHC

- CDA 107 Silver Bearing OFHC

- CDA 110 Electrolytic Tough Pitch

- CDA 113, 114, 117 Silver Bearing

- CDA 122 DHP

- CDA 145 Tellurium Copper

- CDA 150 AMZIRC, Zirconium Copper

- CDA 162 Cadmium Copper

- CDA 172, 173, 175, 17510 Beryllium Copper

- CDA 182 Chromium Copper

- CDA 187 Leaded Copper

- CDA 194, 195 Iron Bearing Copper

- CDA 210 Guilding Brass

- CDA 220 Commercial Bronze

- CDA 230 Red Brass

- CDA 240 Rich Low Brass

- CDA 260 Cartridge Brass

- CDA 268, 272 Yellow Brass

- CDA 280 Muntz Metal

- CDA 314 Leaded Commercial Brass

- CDA 330 Low Leaded Tube Brass

- CDA 353, 356 High Leaded Brass

- CDA 360 Free Cutting Brass

- CDA 464 Naval Brass

- CDA 482, 485 Leaded Naval Brass

- CDA 510 Grade "A" Phosphor Bronze

- CDA 511 Phosphor Bronze

- CDA 521 Grade "C" Phosphor Bronze

- CDA 544 B-2 Phosphor Bronze

- CDA 630 Nickel Bearing Aluminum Bronze

- CDA 642 Aluminum Silicon Bronze

- CDA 651, 655 Silicon Bronze

- CDA 675 Manganese Bronze

- CDA 706 Cupro-Nickel 10%

- CDA 715 Cupro-Nickel 30%

- CDA 725 Cupro-Nickel

- CDA 752, 762, 770 Nickel Silver

- CDA 932 Bearing Bronze

- CDA 954 Aluminum Bronze

Dimensional Precision for Drawn Wire Products

Wire performance depends heavily on consistent diameter, shape accuracy, and surface condition. Metal Associates works with manufacturers that maintain controlled tolerances across round, flat, square, and shaped wire profiles. This supports customers who rely on predictable wire behavior for stamping, forming, winding, and electrical applications where dimensional drift can affect downstream processes.Mechanical Performance and Temper Selection

Wire temper influences strength, flexibility, and forming behavior. Metal Associates provides wire in multiple tempers to support applications ranging from delicate electronic components to high strength mechanical assemblies. Matching temper to application requirements helps maintain stability during bending, coiling, stamping, or repeated flexing.Material Selection for Specialized Environments

Copper, brass, and bronze alloys each offer unique combinations of conductivity, corrosion resistance, and fatigue performance. For environments involving vibration, saltwater exposure, elevated temperatures, or electrical load, Metal Associates evaluates alloy properties to recommend the most suitable material. This ensures long term reliability in marine systems, automotive assemblies, aerospace components, and industrial equipment.FAQ

Can Wire Be Supplied in Custom Shapes or Non Standard Profiles?

Yes. Metal Associates works with manufacturers capable of producing round, flat, square, and shaped wire profiles tailored to specific application requirements.How Do You Determine the Right Alloy for a Wire Application?

Alloy selection is based on conductivity, strength, corrosion resistance, fatigue performance, and environmental conditions. Metal Associates reviews your requirements to recommend the most suitable option.Do You Offer Plated Wire for Electrical or Corrosion Sensitive Applications?

Yes. Plating options include silver, tin, gold, cadmium, and other coatings designed to enhance conductivity, solderability, or corrosion resistance.Can You Support Both Small and Large Wire Orders?

Yes. Flexible production capacity supports prototypes, short runs, and high volume wire programs with consistent quality.

Our Other Products

Metal Associates is a reliable distributor of ferrous and non-ferrous metals. This supplier can provide metals in a variety of shapes including aluminum, brass, copper, bronze, Invar, Cupro-Nickel and more. Metal Associates is committed to providing their customers with outstanding metal products for their projects. These dependable items are long-lasting and this company works with you every step of the way to find you those “hard to find” alloys. There is no project too challenging for their highly trained staff. If you have any special requests then do not hesitate to let one of their representatives know.

Contact Us

Metal Associates

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com