Metal Associates

Distributors of Ferrous and Non-Ferrous Metals

Specializing in Copper, Brass, & Bronze

Copper

-

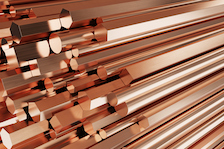

Copper Rod:

Description: Copper rods are cylindrical solid bars made of pure copper or copper alloys. They are typically produced through a process called extrusion or continuous casting.

Applications: Used in electrical applications, such as wiring, and grounding, and in the production of components like electrical connectors.

-

Copper Bar:

Description: Copper bars are similar to rods but are often larger in cross-section. They come in various shapes, including square, rectangular, and round.

Applications: Commonly used in electrical applications, as well as in construction, manufacturing, and as raw material for various copper components.

-

Copper Sheet:

Description: Copper sheets are thin, flat pieces of copper. They can be produced by rolling or hammering copper ingots.

Applications: Used in roofing, architectural applications, electrical projects, and as a raw material for fabrication.

-

Copper Plate:

Description: Copper plates are thicker than sheets and have a larger surface area. They are often used when more substantial thickness is required.

Applications: Commonly used in industrial machinery, construction, and as a base material for various manufacturing processes.

-

Copper Coil:

Description: Copper coils are long, continuous lengths of copper wound in a helical shape. They can be made by winding copper strips or sheets.

Applications: Widely used in electrical components such as transformers, inductors, and electric motors.

-

Copper Foil:

Description: Copper foil is a thin sheet of copper with a thickness typically less than 0.2 mm. It is flexible and can be easily manipulated.

Applications: Commonly used in electronics, as it is an essential component in the production of printed circuit boards (PCBs).

-

Copper Wire:

Description: Copper wires are long, thin strands of copper. They can be solid or stranded (composed of multiple smaller strands).

Applications: Extensively used in electrical wiring, power transmission, telecommunications, and various electronic devices.

-

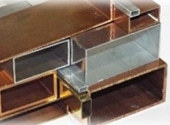

Copper Tubes:

Description: Copper tubes are hollow cylindrical structures with a variety of diameters. They can be seamless or welded.

Applications: Used in plumbing, HVAC systems, heat exchangers, and as conduits for various fluids and gasses.

-

Copper Pipes:

Description: Copper pipes are similar to tubes but are often associated with plumbing applications. They can have different wall thicknesses.

Applications: Widely used in plumbing systems for water supply, heating, and cooling applications.

Various Copper Alloys

Copper alloys are created by combining copper with other elements to enhance specific properties, such as strength, corrosion resistance, conductivity, and machinability. Here's some more information about various copper alloys:

Beryllium Copper (BeCu)

- Composition: Beryllium copper contains copper as the base metal with a small percentage of beryllium (typically 0.5-3%).

- Properties: It is known for its high strength, hardness, and conductivity. Beryllium copper also exhibits excellent corrosion resistance and thermal conductivity.

- Applications: Beryllium copper is often used in applications requiring high strength and electrical conductivity, such as connectors, switches, and various electronic components.

Tellurium Copper (TeCu)

- Composition: Tellurium copper is an alloy of copper with a small percentage of tellurium (usually around 0.5-2%).

- Properties: It has improved machinability compared to pure copper. Tellurium helps in the formation of free-cutting qualities in the alloy.

- Applications: Tellurium copper is commonly used in the production of electrical connectors, switches, and various components where machining is a critical factor.

Oxygen-Free High Thermal Conductivity Copper (OFHC)

- Composition: OFHC copper has a high purity level, typically 99.95% copper or higher, with low levels of oxygen and other impurities.

- Properties: OFHC copper is known for its excellent thermal and electrical conductivity. It is often used in applications where high thermal conductivity is crucial, such as in the production of heat exchangers and electronic components.

Chromium Copper (CrCu)

- Composition: Chromium copper contains copper as the base metal with a small percentage of chromium (typically 0.5-2%).

- Properties: It has good corrosion resistance, high strength, and wear resistance. Chromium improves the hardness and durability of the alloy.

- Applications: Chromium copper is used in applications requiring resistance to wear and corrosion, such as molds, welding electrodes, and electrical components.

Zirconium Copper (ZrCu)

- Composition: Zirconium copper is an alloy of copper with a small percentage of zirconium (usually less than 1%).

- Properties: Zirconium improves the softening resistance and creep resistance of copper. The alloy is known for its high thermal conductivity.

- Applications: Zirconium copper is used in welding electrodes, electrical contacts, and other applications where high thermal conductivity is essential.

Leaded Copper

- Composition: Leaded copper contains a small percentage of lead (typically 0.5-3%).

- Properties: Lead improves machinability and enhances the alloy's ability to form lubricious films during machining.

- Applications: Leaded copper is used in components that require ease of machining, such as bushings and connectors.

Cadmium Copper (CdCu)

- Composition: Cadmium copper contains copper with a small percentage of cadmium (typically 0.1-1%).

- Properties: Cadmium improves the alloy's strength and corrosion resistance. It also enhances the alloy's ability to resist deformation at high temperatures.

- Applications: Cadmium copper is used in applications where strength and corrosion resistance are critical, such as in marine environments and electrical connectors.

Copper’s Role in Modern Electrical Infrastructure

Copper remains the backbone of electrical infrastructure due to its unmatched conductivity, durability, and ease of fabrication. From utility-scale power grids to microelectronics, copper components ensure efficient energy transfer with minimal loss. Its ability to maintain performance under thermal stress makes it indispensable in high-load environments, while its compatibility with various insulation materials supports safe and scalable wiring systems. Highlighting copper’s role in both legacy and emerging technologies helps position your page as a comprehensive resource for electrical-grade materials.

How Copper’s Malleability Supports Complex Fabrication Needs

One of copper’s most valuable traits is its malleability, which allows it to be formed into intricate shapes without cracking or losing structural integrity. This property is especially important in industries like aerospace, medical device manufacturing, and architectural design, where precision and adaptability are critical. Whether it’s deep-drawn tubing, embossed sheets, or custom-milled bars, copper’s formability enables manufacturers to meet tight tolerances and aesthetic requirements without compromising performance.

Comparing Pure Copper to Copper Alloys in Industrial Use

While pure copper offers excellent conductivity and corrosion resistance, copper alloys are engineered to enhance specific mechanical properties. For example, beryllium copper adds strength and fatigue resistance, making it ideal for spring contacts and aerospace components. Tellurium copper improves machinability for high-speed production, while chromium and zirconium alloys offer wear resistance and thermal stability. Understanding these distinctions helps engineers and buyers select the right material for their application, reducing trial-and-error and improving long-term reliability.

Copper’s Sustainability and Recyclability in Manufacturing

Copper is one of the most sustainable metals used in manufacturing, with a recycling rate that exceeds most industrial materials. Recycled copper retains its original properties, making it suitable for electrical, structural, and decorative applications. This recyclability not only reduces environmental impact but also lowers material costs and supports circular economy initiatives. Including copper in eco-conscious sourcing strategies can help manufacturers meet regulatory requirements and corporate sustainability goals without sacrificing performance.

FAQs

What Are the Most Common Forms of Copper Used in Manufacturing?

Copper is typically available as rod, bar, sheet, plate, coil, foil, wire, tube, and pipe, each suited to specific fabrication and electrical needs.

Which Copper Alloy Is Best for Machinability?

Tellurium copper and leaded copper are known for excellent machinability, making them ideal for components requiring precision cutting or shaping.

Can Copper Be Used in High-Temperature Environments?

Yes. Alloys like chromium copper and OFHC copper offer high thermal conductivity and resistance to softening, making them suitable for elevated temperature applications.

What’s the Difference Between Oxygen-Free Copper and Electrolytic Tough Pitch Copper?

Oxygen-free copper (OFHC) has higher purity and conductivity, ideal for sensitive electronic and thermal applications. ETP copper contains trace oxygen and is more common in general electrical use.

Our Other Products

Contact Us

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com