Metal Associates

Distributors of Ferrous and Non-Ferrous Metals

Specializing in Copper, Brass, & Bronze

Bronze

Metal Associates can fulfill its customer’s bronze needs from bronze sheets to bronze foil. Like brass, bronze is one of the more popular of copper alloys, making it the most commonly used alloy of this non-ferrous metals. The mixture of tin and copper results in bronze, an alloy that is less brittle than tin and iron, but harder and more durable than pure copper. The exact amount of copper in bronze is extremely variable and ranger from 60% to nearly 90% in some commercial grades. The second most prevalent element in bronze is tin, which is also variable commonly composing between 12% and 40% of the alloy. Bronze metal is easier to melt, making it easier to make products from bronze basting. Additional elements such as manganese, lead, zinc, silver, phosphorous, arsenic can also be added to enhance specific features of special-purpose bronzes. These and other less complex varieties of bronze are available to suit a wide range of industrial applications.

Whatever the application, let Metal Associates be your next bronze suppliers.

Whatever the application, let Metal Associates be your next bronze suppliers.

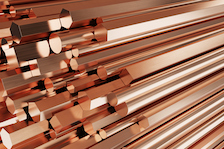

Available in Various Forms:

- Bronze Rod

- Bronze Bars (Rectangular, Hexagon, and Square)

- Bronze Sheets and Bronze Plates

- Bronze Coil

- Bronze Foil

- Round, Flat and Square Bronze Wire

- Bronze Tubes and Bronze Pipes

The Versatility of Bronze in Industrial Applications

Bronze is a foundational material in industrial design thanks to its strength, corrosion resistance, and low-friction properties. Its core composition of copper and tin can be modified with elements like aluminum, silicon, or manganese to enhance specific performance traits. This flexibility allows manufacturers to select bronze grades tailored to demanding environments, such as marine systems, heavy machinery, and electrical assemblies. Its ability to resist wear and galling makes bronze especially valuable in applications involving repeated motion or metal-on-metal contact.Alloy Selection for Performance and Reliability

The wide range of bronze alloys available, such as CDA 954 Aluminum Bronze and CDA 932 Bearing Bronze, enables engineers to fine-tune material selection based on mechanical load, thermal conditions, and environmental exposure. For example, aluminum bronze offers excellent strength and corrosion resistance, making it ideal for pump components and valve stems, while phosphor bronze is preferred for electrical connectors and springs due to its fatigue resistance and conductivity. Understanding these alloy distinctions helps buyers make informed decisions that reduce downtime and extend service life.Bronze in Design, Fabrication, and Sustainability

Bronze’s historical reputation for durability continues to hold true in modern manufacturing. Its ease of casting and machining makes it a reliable choice for custom components, especially when precision and repeatability are important. In addition to its mechanical advantages, bronze also offers aesthetic appeal, with a warm, reddish-gold tone that’s often used in architectural accents, sculptures, and decorative hardware. Its ability to develop a natural patina over time adds character while protecting the surface from further oxidation. Bronze is also a sustainable material, with excellent recyclability and minimal degradation during reprocessing. Recycled bronze retains its original properties, making it suitable for high-performance applications without compromising quality. This makes it a smart choice for manufacturers focused on reducing waste, lowering material costs, and meeting environmental standards.FAQs

What Is the Difference Between a Bronze Rod and Bronze Bar?

Bronze rods are typically round and used for uniform-diameter components, while bronze bars come in square, rectangular, or hexagonal profiles for structural or machined parts.Which Bronze Alloy Is Best for Bearings and Low-Friction Applications?

CDA 932 Bearing Bronze is widely used for bushings and bearings due to its excellent wear resistance and low metal-on-metal friction.Can Bronze Be Used in Marine Environments?

Yes, bronze is highly resistant to corrosion in saltwater, making it ideal for marine hardware, propellers, and underwater fittings.Alloys Available:

- CDA 510 Grade "A" Phosphor Bronze

- CDA 511 Phosphor Bronze

- CDA 521 Grade "C" Phosphor Bronze

- CDA 544 B-2 Phosphor Bronze

- CDA 630 Nickel Bearing Aluminum Bronze

- CDA 642 Aluminum Silicon Bronze

- CDA 651, 655 Silicon Bronze

- CDA 675 Manganese Bronze

- CDA 706 Cupro-Nickel 10%

- CDA 715 Cupro-Nickel 30%

- CDA 725 Cupro-Nickel

- CDA 752, 762, 770 Nickel Silver

- CDA 932 Bearing Bronze

- CDA 954 Aluminum Bronze

Applications

Bronze is used for many different industrial applications, and it’s an important material for industries like marine technology, electrical assembly, automotive and more. Bronze can be used to make springs, turbines and blades. It’s also a common choice for machine bearings because it has such low metal-on-metal friction. In marine settings, bronze is a popular material because it is highly resistant to corrosion.Get every kind of bronze alloy from Metal Associates today! From bronze rod to bronze wire, we’ve got it all.

Services

We know that sometimes the only way for you to get the solution that you need is with custom metal. That’s why our services include:- Custom slitting

- Edging

- Cut to length and leveling

- Polishing

- Centerless ground

Superior Service from Metal Associates

At Metal Associates, our objective is always to offer superior service. As soon as you contact us, your needs are our first priority. We believe in building strong and long-lasting relationships with all of our customers so that they know where to turn when they need quality metals in the future. Contact us today to find to why we are a superior metal supplier! From stock products to custom metal orders, we’re ready to help you.

Our Other Products

Metal Associates is a reliable distributor of ferrous and non-ferrous metals. This supplier can provide metals in a variety of shapes including aluminum, brass, copper, bronze, Invar, Cupro-Nickel and more. Metal Associates is committed to providing their customers with outstanding metal products for their projects. These dependable items are long-lasting and this company works with you every step of the way to find you those “hard to find” alloys. There is no project too challenging for their highly trained staff. If you have any special requests then do not hesitate to let one of their representatives know.

Contact Us

Metal Associates

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com