Metal Associates

Distributors of Ferrous and Non-Ferrous Metals

Specializing in Copper, Brass, & Bronze

Brass Coils

Brass is a metal alloy that is made from combining copper and zinc. The proportions of the two metals can be varied to create different types of brass with distinct properties and characteristics. This particular aspect of brass makes it an ideal material for the creation of coils since the qualities, shapes, and configurations of the coils can be adapted to fit any application.

The variations of the types of brass make it possible to create brass coils that exactly fit the needs of a project or design. The malleability of brass makes it possible to shape, form, and adjust it to the perfect dimensions for a coil winding.

As with any type of coil, the winding of brass is a critical part of the coil manufacturing process since the type of winding has to be precisely calculated to ensure the efficiency and accuracy of the coil. Metal Associates experts and engineers plan every detail of the process of the manufacture of brass coils down to the most minute detail.

In Metal Associates production of brass coils, thin sheets of brass are cut into strips to be wound around a core. The lightweight of brass and its small diameters makes it perfect for doing tight and secure windings. Since brass is so ductile, it can be shaped, cut, configured, and formed to fit any type of core using different lengths, dimensions, and tolerances.

Brass coils are a cost-effective solution for precision coil production. The brass material can be drawn into very thin wire with little resistance to electrical current, making it ideal for use in industrial projects that include cables, long distance power supplies, and underground railroads.

Metal Associates takes advantage of the many qualities of brass, especially its ductility and malleability. These characteristics make it possible to form the brass into flat, rounded, or annealed wiring.

The variations of the types of brass make it possible to create brass coils that exactly fit the needs of a project or design. The malleability of brass makes it possible to shape, form, and adjust it to the perfect dimensions for a coil winding.

What is a Brass Coil?

Brass is a very versatile alloy that is easily shaped with excellent heat and electrical conductivity. These properties make it ideal for use as a coil. The small amount of zinc in brass enhances its properties and improves its strength to make it more durable for stressful and constant use.As with any type of coil, the winding of brass is a critical part of the coil manufacturing process since the type of winding has to be precisely calculated to ensure the efficiency and accuracy of the coil. Metal Associates experts and engineers plan every detail of the process of the manufacture of brass coils down to the most minute detail.

Uses for Brass Coils

There are many applications that require a conductor that is lightweight, easy to shape, has a small diameter, and fits into any configuration. For those conditions, brass coils are the ideal choice due to brass’ high conductive properties, corrosion resistance, and strength. A key feature of brass is its durability and capability to withstand constant abuse. It is for this reason that brass is found in musical instruments.In Metal Associates production of brass coils, thin sheets of brass are cut into strips to be wound around a core. The lightweight of brass and its small diameters makes it perfect for doing tight and secure windings. Since brass is so ductile, it can be shaped, cut, configured, and formed to fit any type of core using different lengths, dimensions, and tolerances.

Brass Coils by Metal Associates

Metal Associates uses the highest quality brass wire to manufacture its brass coils. The many positive properties of brass make it an excellent material for the manufacturing of electrical coils. Though it has high conductive properties, brass wire still has the endurance and resilience to withstand the rigors of harsh conditions. This long-lasting quality enhances the performance of brass coils and makes them perfect for serving as an essential element in electrical circuits.Brass coils are a cost-effective solution for precision coil production. The brass material can be drawn into very thin wire with little resistance to electrical current, making it ideal for use in industrial projects that include cables, long distance power supplies, and underground railroads.

Metal Associates takes advantage of the many qualities of brass, especially its ductility and malleability. These characteristics make it possible to form the brass into flat, rounded, or annealed wiring.

Brass types offered by Metal Associates:

- CDA 210 Gilding Brass

- CDA 220 Commercial Bronze

- CDA 230 Red Brass

- CDA 240 Rich Low Brass

- CDA 260 Cartridge Brass

- CDA 268, 272 Yellow Brass

- CDA 280 Muntz Metal

- CDA 314 Leaded Commercial Brass

- CDA 330 Low Leaded Tube Brass

- CDA 353, 356 High Leaded Brass

- CDA 360 Free Cutting Brass

- CDA 464 Naval Brass

- CDA 482, 485 Leaded Naval Brass

About Us

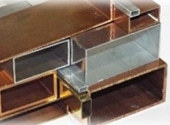

Metal Associates is a metal supplier that specializes in the distribution of high quality copper, brass and bronze products. Along with those, we supply customers all across the board with ferrous and non-ferrous metals and metal alloys such as aluminum, carbon steel, cupronickel and invar. In addition, because we are a full line distributor, we are able to offer our metal products in virtually all shapes, sizes and tempers. In addition to our metal and stock metal shape products like brass plates, we offer products, such as waveguide tubing and lock wire, for specific applications. Here at Metal Associates, we are committed to providing our customers with outstanding metal products for their projects that are long-lasting and reliable. We believe in quality. To make sure that you are satisfied and that you get those “hard to find” alloys that you are looking for; we will work with you every step of the way. There is no project too challenging for our highly trained staff. If you have any special requests then do not hesitate to let one of our representatives know. Call, email, fax us or submit an information request to learn more. We cannot wait to work with you.Our Other Products

Metal Associates is a reliable distributor of ferrous and non-ferrous metals. This supplier can provide metals in a variety of shapes including aluminum, brass, copper, bronze, Invar, Cupro-Nickel and more. Metal Associates is committed to providing their customers with outstanding metal products for their projects. These dependable items are long-lasting and this company works with you every step of the way to find you those “hard to find” alloys. There is no project too challenging for their highly trained staff. If you have any special requests then do not hesitate to let one of their representatives know.

Contact Us

Metal Associates

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com